Teaming up with US SOCOM, US ARMY ARDEC, and Lawrence Livermore National Laboratory (LLNL) to develop a model based design code to simulate the phenomenon occurring inside weapons suppressors.

This allows the researchers to understand what is really happening inside suppressors, allowing better designs and more functional weapons platforms. These high fidelity codes run on high performance multi processor computers. These computers were used to determine how the gas flows from the muzzle to the exit of the suppressor while reducing the pressure. By manipulating the interior structure of the suppressor, and moving away from a traditional baffle design, we were able to design the system to change the rate of flow of the gas exiting the suppressor before and after the bullet. By stretching the time, it takes the gas in the suppressor to vent from the initial pressurization, we minimize the acoustic signature.

Our roots in the aerospace industry and partnership with Oak Ridge National Labs (ORNL) have allowed us to work with some of the most advanced super alloys in the world, along with some of the brightest minds our nation has to offer. The continual development of these alloys will allow us to continue to push the limits of suppressor capability well into the future. We currently use 718 Inconel in all our suppressors. Inconel 718 is a well understood nickel super alloy that is known for its exceptional properties at high temperatures. This makes 718 Inconel a great fit for suppressors and offers durability far superior to titanium, stainless steel or aluminum suppressors currently on the market.

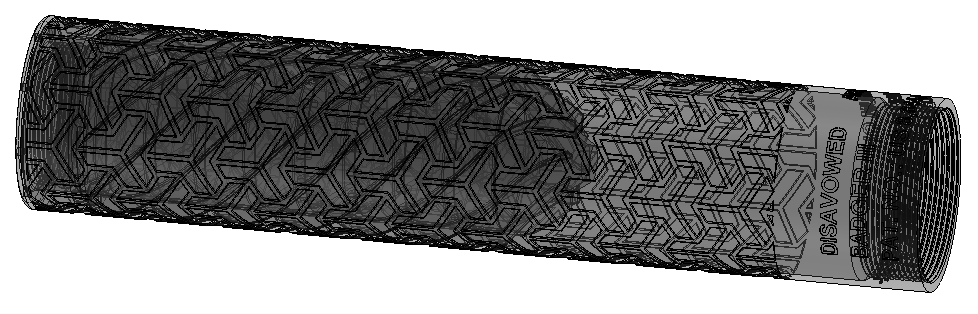

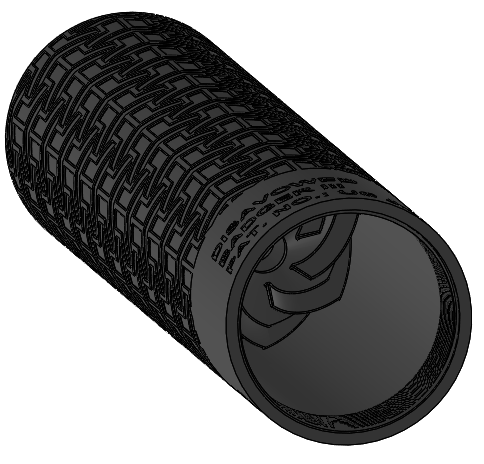

The technology that was developed during the SOCOM program have been optimized by Disavowed Group using the 3-D model codes, and 3-D printed from Inconel 718. When compared to a standard OEM suppressor typically used by the military, the designs were superior on several fronts including Acoustics, Heat Buildup, Back Pressure, and Flash.

All of our suppressors are produced by additive manufacturing, specifically the selective laser melting process. These machines are highly customized by industry experts to allow us to achieve the highest quality possible. Selective laser melting is the same technology that is currently being used in the aerospace industry to print both structural aircraft components and turbine engine components. These complex designs can only be realized through additive manufacturing technology. Disavowed Group uses science while the majority of the industry continues to use the common machined and welded traditional baffle stack based on ideas that have been around since before man went into space.